Small Business Manufacturing Software: On-time Deliveries

Lead-time Reduction Leads to Success: Small Business Manufacturing Software

Hello again,

This post is for manufacturers with small businesses or medium sized companies. We hope you find this information useful.

One of the more difficult benefits to quantify from a good ERP system is the ability to reduce lead-times on products you make and sell. However, this can be one of the greatest benefits of implementing such a system.

Become more competitive

Today’s manufacturing market is as competitive as it’s ever been. Price pressures from the global market have been a large reason for this.

The world seems to be getting smaller and smaller allowing many foreign manufacturers to compete in the US. In addition, with the economic struggles over the last few years companies have been reducing margins to retain business.

This begs the question how can a US manufacturer, with higher costs than many of their overseas counterparts compete?

The answer is simple, respond faster with the same or better quality! In other words, reduce your products’ lead-times to the point where you can get product to your customers faster, and more efficiently than your competitors.

To achieve this you will need to do a few things:

1. Maintain a perpetual inventory system

2. Implement a material planning system

3. Implement an order management system

4. Use these to their fullest extent

Automate with small business manufacturing software

This sounds complex, but it’s really not as difficult as it sounds. Often, smaller manufacturers are getting by with some combination of paper, spreadsheets, and computer software not designed to meet their manufacturing needs. The first automation project in a manufacturing company tends to be in the accounting area.

Little thought is put into the needs of the rest of the operation. This generally leads to the need for spreadsheets, external database applications, paper, or information locked up in an individual’s head. The result is typically poorly managed data which leads to an inefficient operation.

Visibility

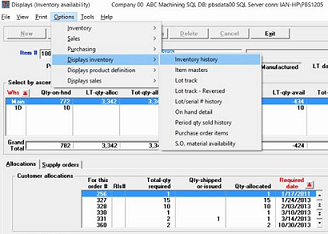

When you bring all of this information together into a unified application, where visibility is available across the entire operation, suddenly your information becomes the foundation for a “decision support system.”

Small business manufacturing software can help you make more intelligent decisions about things like what to order and when to order them, or customer demands and how to act on them.

How does this result in reducing product lead-times? As soon as an order is placed by a customer, information about the material needed to produce the order is immediately made available to the production and purchasing departments.

This results in a more timely response to the needs which results in raw materials being brought in quicker. Material being ordered in a timely fashion results in it being available when production needs it to manufacture the order. This goes a long way towards getting your products to your customers when they want them.

Compress Lead-times

In addition, a company can also begin to include things like safety stock or re-order points on key items ensuring that they have key items in stock at all times. This alone can dramatically reduce the overall lead-time of a product.

When you consider that some raw materials can have lead times of several months, you can literally compress the lead-time of a finished product to days.

These are only two of many reasonably simple examples of how an ERP system can aid you in reducing product lead-times. When correctly deployed, your small business manufacturing software system can dramatically reduce your product lead-times resulting in a leaner operation, higher customer service levels, and increased sales.

The right ERP system will be able to improve your market position for the very same reasons.

Learn more about our Small Business Manufacturing Software for small to mid-sized operations. Or contact Dave Dorsey at ddorsey@pass-port.com or 800-969-7900 x145.