PBS™ Manufacturing – Set Order Planning Rules

Hello again,

This post is for small and medium-sized manufacturers that are vetting new manufacturing software systems. We hope you find it useful.

A Material Requirements Planning tool provides concise reporting with order suggestions. This planning tool allows you to have inventory you need on-hand for “just-in-time” planning and on-time shipping.

Utilizing Material Requirements Planning can help offset the impact of higher interest rates and supply chain challenges by providing better visibility and facilitating flexible order planning and purchasing.

The need for various components depends on the demand for your end product, and these parts are built into the bill of materials. The BOM breaks down parts and their relationship to subassemblies and finished goods. An effective MRP system allows you to easily update order priorities, at any point in time, as schedules fluctuate.

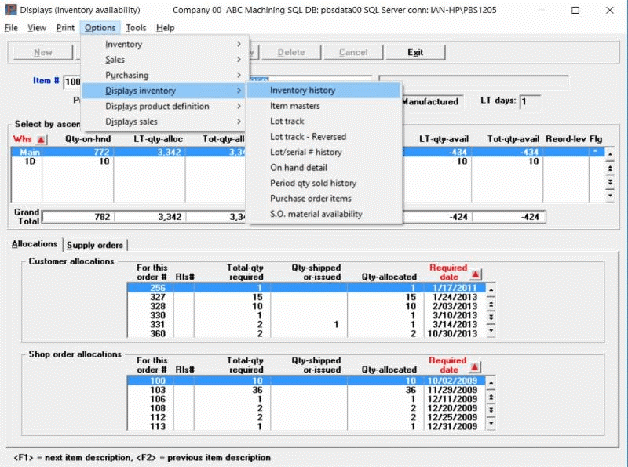

An MRP master schedule takes into consideration inventory levels, lead times, open order commitments, and also forecasts future demand. It provides planning functions for sales, production, and inventory requirements.

The PBS™ Manufacturing MRP tool helps improve delivery times, reduce inventory levels, and ensures that necessary parts are on-hand. It is useful for planning in response to actual demand as well as to sales forecast or a combination of the two.

Expedite an Order

An MRP tool may recommend that you expedite an order, meaning you can request an expedited delivery date for the needed component. It may also recommend that you de-expedite the delivery date of an order, moving less important orders to a later date to prioritize more crucial orders.

Better control of delivery dates reduces inventory backstock and helps ensure you are not waiting for necessary parts. Having the components you need ensures steady production and prevents operational inefficiency and delays.

If your shop is experiencing production delays, bottlenecks, carrying costs for too much backstock, MRP can improve productivity and reduce inventory levels.

If your operation is running relatively smoothly, Material Requirements Planning can be useful when experiencing an unexpected uptick in demand or significant growth that requires greater production capacity. An outdated system or manual tracking may not withstand this increased demand.

PBS™ Manufacturing

The PBS™ Manufacturing Material Requirements Planning module allows you to:

– Set Planning Rules: Safety stock level, Order minimum, maximum and more

– Set Lead Time to have materials on hand and ship orders on time

– Concise Reporting with order suggestions to act accordingly

PBS™ Manufacturing is a scalable modular solution, so the MRP module integrates with other modules to meet your company’s unique needs.

Our Material Requirements Planning module is included in the Planning Bundle. In addition to the Basic Bundle, the Planning Bundle includes the Master Scheduling & MRP and the Capacity Planning modules.

Call 800-969-7900 to learn more about PBS Manufacturing ERP, an affordable yet robust system designed to serve the needs of small to mid-sized manufacturers. Or, contact us – we are here to help.