Quirk Wire Creates a Competitive Advantage with PBS™ Manufacturing ERP

From a letter sent to Paul, LaFlamme, owner of Centrend, a PBS Manufacturing Software Partner in Central Massachusetts dated February 1, 2012: I just wanted to thank you and the Centrend team for a great ERP implementation. When we first met, you showed us how it could make a big difference in our business. We’re a couple months shy of the one-year anniversary of implementation and I had no idea the results would be this dramatic. I want to share with you what we’ve been able to realize from these efforts:

Inventory Visibility

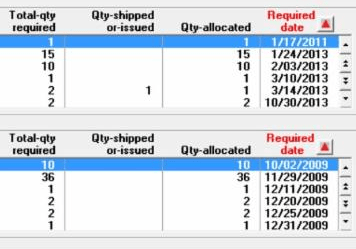

- We now have raw material, stock room, and Finished Goods inventory visibility which many on our management team didn’t think was even possible due to the seemingly infinite number of variations of wires and cables we can manufacture

- We are no longer making things we shouldn’t while still stocking components that need to be stocked

- Sales no longer needs to be out on the floor or in the stock room trying to determine what we have or what we can make to meet customer requirements.

Shop Automation

- Implementing Bar Coding at all the workstations seemed like a big task – it was such a quantum leap from the manual recording we were doing. Instead you kept it simple and our production employees now spend less time writing and logging and retagging product and have more time for working on the product in ways that add value.

- We know exactly where any job is on the shop floor. We don’t have to go around and find things to see what’s going on with a particular order.

- We can see how much scrap has been realized through data collection and even more importantly, “unreported scrap” which shows us true yield so we can price product correctly.

Smoother, Faster, and Leaner Business Processes

- Rather than dovetail PBS Manufacturing into what we were already doing, your consulting sessions really helped us (forced us!) to look at our business processes in new ways which drove us toward an optimal process.

- Lead time on highly customized cables was reduced from thirteen weeks to six weeks.

- Lead time on custom single lead wires was reduced from 8 weeks to 4 weeks.

- Common stock cables that used to be made with the custom single leads can now get out in days because of the creation of an express “Fast Lane” for these items.

- The custom reporting you’ve done for us has really helped us make informed, timely decisions on raw material purchases and planning our manufacturing schedule.

All in all, your Passport PBS Manufacturing implementation has helped us create a huge competitive advantage and will have a positive long term, ongoing impact on our bottom line. We are driving toward very accurate estimation of lead times and as a result, the very important goal of 100% on-time shipments.

Thank you again for the great results!

Sincerely,

David Thibodeau

President

Quirk Wire, Co. Inc.

Call 800-969-7900 to learn more about PBS Manufacturing ERP, an affordable yet robust system designed to serve the needs of small to mid-sized manufacturers. Or, contact us – we are here to help.