Manufacturing Software for Growing Companies

Hello again,

This post is for small and medium-sized manufacturing companies that are vetting new manufacturing software systems. We hope you find it useful.

According to The Manufacturer, a recent survey conducted by the Federal Reserve Bank of Kansas City showed notable expansion in manufacturing activity in midwestern/western states.

The manufacturing sector in Missouri, Kansas, Colorado, Nebraska, Oklahoma and Wyoming has shown significant growth for almost a year.

“Regional factories reported historic growth and very positive expectations in April,” according to Chad Wilkerson, V.P of the Federal Reserve Bank of Kansas City.

He explains, “Compared to pre-pandemic levels, new orders and employment have risen for some contacts, but varied by industry.”

Manufacturers producing durable goods, fabricated metals, and transportation equipment are among those most likely to have shown growth.

However, some manufacturing operations are facing a labor shortage.

Labor Shortage

“U.S. factories desperate for workers, even as ranks of jobless remains high… factories around the country are seeing vacancies go unfilled,” states a recent article from Reuters.

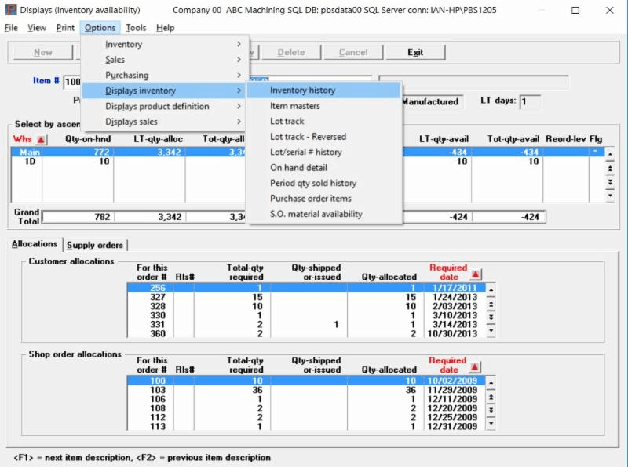

PBS™ Manufacturing software for small businesses helps facilitate more throughput with fewer employees. Thus freeing up staff for other operation-critical duties.

In addition to a possible labor shortage, many manufacturers are still facing supply chain issues and higher prices for sourced materials.

Our manufacturing system helps you effectively manage purchasing, track supply costs, and set alternate suppliers in your system.

Vetting a New System

Rather than implementing digital transformation solely from the top down, it’s important to involve key employees in the decision-making process.

Frontline employees encounter ground level issues and can offer input and clarity about the approach needed when vetting a new manufacturing system.

Involving both high-level decision makers and key employees can streamline the process of selecting new Manufacturing ERP software that meets your company’s unique needs.

A savvy employee can help delineate the specificity needed to meet the unique challenges of your process, as well as identify systematic problems to be solved in the workflow.

A top-down only approach may miss out on some honest employee assessments about operational challenges that need to be addressed.

Your Company’s Unique Processes

Passport Software helped one company whose management thought there was a workflow problem on the front line.

After interviewing employees, it turned out that the plant manager hadn’t yet designated a sole purchasing manager.

Hence the right components were often unavailable, so workers had to constantly stop and start on jobs, wasting time and money.

Front line employees can contribute a solid and detailed understanding of the workflow in order to help digitize your processes. They can help ensure the new manufacturing system will streamline processes effectively.

Leaving front line employees out of the vetting process might result in missed underlying issues in current processes that could hamper the efficacy of the new system.

Also, leaving key employees out of the process might affect employee buy-in, as workers with “stake in the game” tend to feel included. They may be more likely to work properly with a system they helped approve.

To learn more about PBS Manufacturing software for small businesses and mid-sized companies, call 800-969-7900. Or, contact us – we are here to help.