Small Business Manufacturing Software Vetting and Implementation

Tips for Vetting Your New Manufacturing System

Hello again,

This post is for small and medium-sized companies that are vetting new manufacturing software systems. We hope you find it useful.

Since 2020, many manufacturers have adapted their processes and systems to meet challenges in the marketplace and cope with disruptions in the supply chain.

Many manufacturers continue to digitally transform their ERP or manual tracking systems in order to streamline operations, increase throughput, and increase profitability.

Implementing or replacing an outdated ERP system is a critical undertaking requiring expert consulting in order to select the proper system and ensure the new system is a good fit for your company.

Vetting a Manufacturing ERP System

When vetting a new manufacturing system, it’s important to have leadership and the right employees involved in the project. Key employees can provide critical operational knowledge, and involving them will also help with employee buy-in.

Strategic decision making during the vetting process may evolve as crucial information from key employees comes into play. Partnering with an expert consultant can ensure you meet your business goals and help you tailor a new system to meet your company’s unique needs.

If you are manually tracking operational data, make sure to inform your potential vendor about your most complex processes, current bottlenecks, and areas needing improvement.

For those wanting to replace an outdated manufacturing system, make sure to let your consultant know about workarounds you’re using or processes your current system cannot manage.

Any processes unique to your business should be communicated as well, in order to ensure the vetting process is thorough.

Passport Software

Vetting a new Manufacturing ERP system, implementation, and training on a new system are big undertakings. Our expert consultants have the experience to help you determine if our manufacturing software is a fit for your operation.

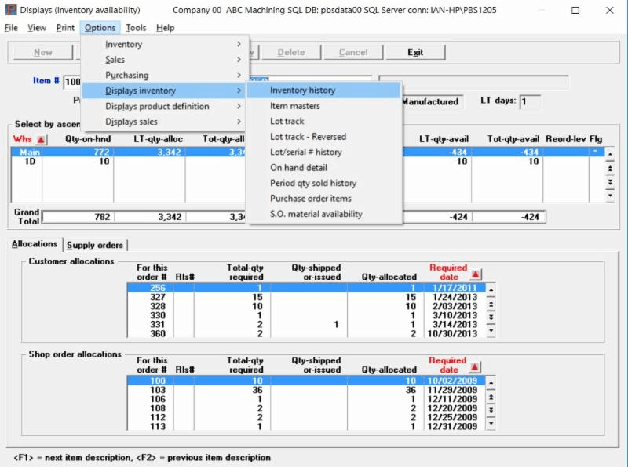

Passport Software’s manufacturing software for small businesses is a powerful yet affordable solution for small and medium sized operations.

We are experienced in change management and can help you facilitate a smooth implementation process and we provide excellent training and support as well.

PBS™ Manufacturing is a modular solution tailored to fit a company’s unique needs, so you can add on as your company grows.

To learn more about our manufacturing software for small businesses and mid-sized operations call 800-969-7900. Or, contact us – we are here to help.