PBS™ Manufacturing Facilitates Lead Time Reduction

This article is for small and medium-sized manufacturers that are vetting new manufacturing software systems. It was written by Ian Creswell, Passport Software’s Executive Vice President/Manufacturing Product Manager, and we hope you find it useful.

We often talk about numerous features and benefits when we discuss PBS™ Manufacturing ERP with new companies; better material planning, better production scheduling, inventory reduction and more.

Something that probably doesn’t get enough attention is something I like to call a “side effect”- lead time reduction for on-time deliveries.

Improve Lead Times

Lead time reduction can result in a massive improvement in your ability to compete in your industry.

Here’s a great quote from a PBS Manufacturing customer who manufactures cables in Western Massachusetts. They worked with a Passport Partner in the same region that helped them deploy PBS and shared this one year after going live:

“Your consulting sessions really helped us (forced us!) to look at our business processes in new ways which drove us toward an optimal process.

- Lead time on highly customized cables was reduced from thirteen weeks to six weeks.

- Lead time on custom single lead wires was reduced from 8 weeks to 4 weeks.

- Common stock cables that used to be made with the custom single leads can now get out in days because of the creation of an express “Fast Lane” for these items.

- The custom reporting you’ve done for us has really helped us make informed, timely decisions on raw material purchases and planning our manufacturing schedule.”

If you’re doing the math, this manufacturer saw more than a 50% reduction in lead times on many of their products.

Benefits

How could they possibly have achieved this? These improvements are what can aid a company in seeing a dramatic improvement in product lead times:

- Better material planning – production can’t make an item if they don’t have the raw materials or even the sub-assemblies required to do so. This is a common problem with smaller shops that aren’t running an ERP solution designed for manufacturing. A basic inventory system typically doesn’t cut it.

- Better production scheduling – having the materials you need is critical, but so is knowing exactly what you need to be producing and when it falls right in line. PBS can aid you in building complex schedules with ease while helping you plan to have the material to support this.

Combining the two of these, and introducing some simple concepts such as setting good re-order levels on high-use raw materials, helps ensure you have the materials to turn over orders faster – without building out unnecessary inventory carrying costs.

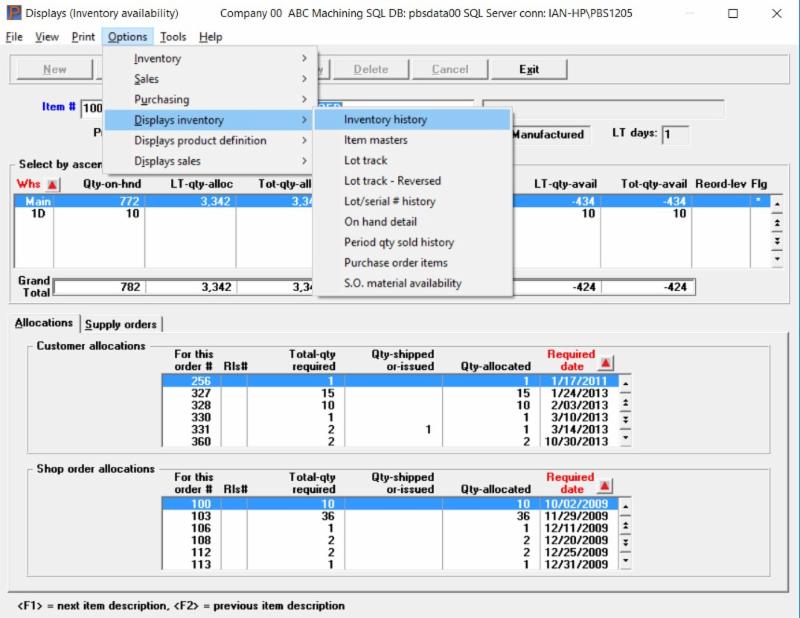

As you begin building history, PBS provides tools that help determine these numbers to assist you in planning for the materials you do need and not bringing in unnecessary inventory at the same time. Reduction of lead time is your side effect. The other is often a reduction of inventory and higher inventory turns.

Now couple that with reliable production scheduling, ensuring each step of the process is completed before the next is needed, and you too can experience the side effect.

PBS™ Manufacturing ERP is modular in design and integrates with PBS™ Accounting to adapt to your unique needs and processes. You can select only the modules you need and scale up as you grow.

Call 800-969-7900 to learn more about PBS Manufacturing ERP, an affordable yet robust system designed to serve the needs of small to mid-sized manufacturers. Or, contact us – we are here to help.