Automated Gasket Improves Financial Position with PBS™ Manufacturing Software

Automated Gasket was founded in 1994 by Terry Brown and Allen Coles to provide contract gasket making services. Being in Oklahoma City, OK, it’s no surprise that they originally targeted the oil industry.

Today, the company is solely owned by Terry M. Brown and they serve many different industries including telecommunications, computer, electric motors, medical, automotive as well as many others.

Back in 2009, Terry attributed much of their success to computer automation. He was referring specifically to die stamping machines that were computer controlled. “These computer-driven machines have given us the ability to react and respond quickly to meet a customer’s specific needs,” Brown said.

“For example, the old die-stamping machines were labor intensive and usually required a day’s time to recalibrate, but with computerized resetting, we can cut that tooling time to about 15 minutes.” And the machinery is adaptable from industry-to industry.

Automation

Around the same time, Automated Gasket decided it was time to automate their business systems. They were using an older version of an accounting/distribution software application that worked pretty well for their accounting needs, but didn’t work very well for their manufacturing operation.

There were restrictions in the inventory package that made it very difficult to use in their operation and they were struggling with its lack of visibility.

They were also finding it very difficult to get support on their application. In addition, it was very outdated, and they’d been told that the version they were running couldn’t be upgraded. They were left starting over from scratch.

It was at this time that Terry contacted Softech Corporation in nearby Bethany, OK, a business systems solution provider. He had personal ties to the owner, Jon Ritchey and decided since they had to start over again anyway, perhaps it was time they began to automate the way the rest of their operation was run.

Review

After a detailed review of the problems they were faced with, Jon introduced Automated Gasket to Passport Software, Inc.’s PBS Manufacturing. After carefully reviewing the capabilities of PBS Manufacturing, it was selected as the new ERP system for Automated Gasket.

Over the coming months, Jon worked with Ian Creswell, one of Passport’s manufacturing business consultants, to help Automated Gasket implement and begin reaping the benefits of PBS Manufacturing in their operation.

Visibility

In a recent interview, Shonna Cartmell, Automated Gasket’s Purchasing Manager and lead on the PBS Manufacturing implementation project, stated “The best part of implementing PBS Manufacturing was the dramatic improvement in visibility. It’s like day and night compared to what we used to have.

We had virtually no visibility of inventory, commitments of that inventory, or when and where it was needed. We had no real planning capability so it was difficult to know what to order when.

This made it difficult for us to have the right inventory at the right time and often led to us carrying more inventory than we really needed.”

Basic Bundle

Automated Gasket Company purchased and implemented PBS Manufacturing along with the PBS Accounting which ensured they would have a fully integrated business management system.

Though they only invested in the PBS Manufacturing “Basic Bundle”, they’ve still been able to achieve remarkable improvements in the visibility of all of their business data.

Order Turnaround Times

“One of the areas that has really helped us improve our financial position is in the area of inventory turns. With the new-found visibility, we now know exactly what materials we need to bring and when we need them.” said Cartmell. “This allows us to keep less material on hand while still keeping our order turnaround times down. It also has helped us reduce the amount of inventory we have on hand at any given time.”

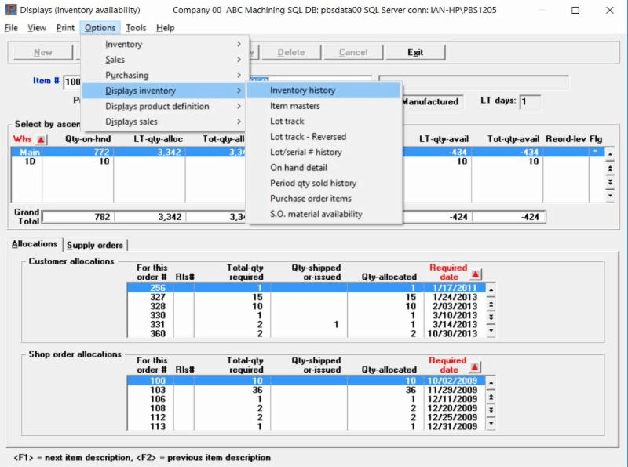

“The best part of our implementation was the ability to see my inventory commitments in the Inventory Availability program. It shows me everything; what we have, what we need, and exactly when and where it’s needed all on one screen!”

Call 800-969-7900 to learn more about PBS Manufacturing ERP, an affordable yet robust system designed to serve the needs of small to mid-sized manufacturers. Or, contact us – we are here to help.