PBS™ Manufacturing Software for Small to Midsized Companies – Make To Stock

A manufacturing company making product to stock is faced with their own unique needs; knowing which items to build when, predicting which raw materials to have on hand, how much to carry, and when it’s time to re-stock the shelf among others.

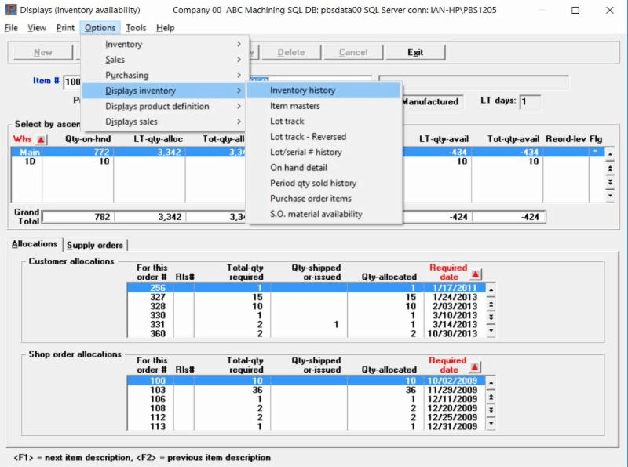

PBS™ Manufacturing is an ERP software solution that will help ensure you have the materials you need when you need them.

Whether you choose to use our simple re-order level planning, our complete Material Requirements Planning module with sales forecasting, or a combination of the two, you can be sure you will have the materials you need at all times.

Our order action reporting will help take the complexity out of your material planning function. You will be able to turn over orders faster than ever.

Not only can this aid you in having the inventory you need, it can help you avoid bringing in materials you don’t. Many companies find they can reduce inventory while still having the material they need on-hand.

This can improve customer service levels and reduce your inventory carrying costs. Here’s a link to a video discussing this very topic.

Add in our optional shop floor scheduling, capacity planning or costing tools and you can have a complete business solution for a minimal investment!

PBS Manufacturing software for small businesses and midsized companies can help you know your costs. And, it helps you know exactly what needs to be done at all times ensuring you are profitable, and that your customer’s orders are going out on time!

“When I look up our inventory, I can say that I have confidence in the numbers – it has never let us down. I don’t have to go find out if we have something and count it myself to know what we have.” – Bill Allhusen, Engineering Manager, Cosense, Inc.

“…the added planning capabilities helped improve on-time deliveries significantly by achieving a better flow of inventory. All of this was accomplished without adding a single employee.” – Chuck Bauman, General Manager, Dazor Manufacturing Corporation

Call 800-969-7900 to learn more about PBS Manufacturing ERP, an affordable yet robust system designed to serve the needs of small to mid-sized manufacturers. Or, contact us – we are here to help.